Versant-180i-170i-Press

Overview

Further Improvements to the Versant Series.

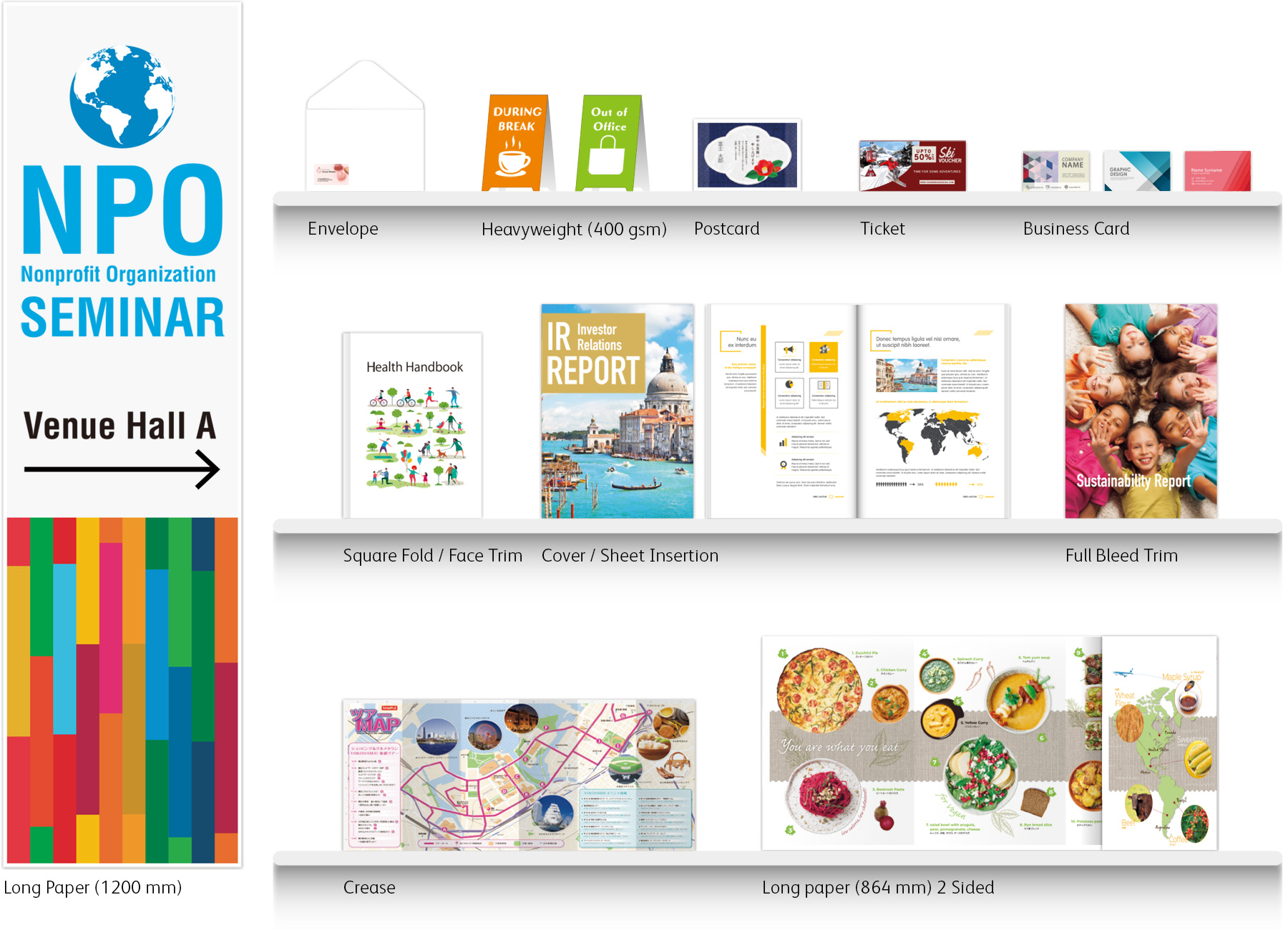

Versant 180i / 170i Press prints photos, text, and various document types in high resolution quickly and accurately. In addition to the attractive finishing features of the Versant series, it can also handle long paper, heavyweight paper, and a wide variety of applications. It comes in a compact size with full office functions.

- Note: Samples include those that require separate finishing.

Features

Top-Level Productivity and Versatility with Endless Possibilities - Versatility & Productivity

Maximum Speed at 80 ppm*1, Fast Printing even for Long Paper and Mixed Jobs

The high-performance print engine achieves excellent productivity of 80 ppm*1. Image quality adjustment is also optimised during changing of paper and there is no downtime when printing mixed jobs*2 of coated and uncoated paper. High utilisation rate is achieved. The new Air Suction Feeder also prints long paper of 330 x 1200 mm at 12 ppm. Long paper printing is 2 times*3 faster (in-house comparison).

- *1: For Versant 180i Press. 70 ppm for Versant 170i Press. 52 to 220 gsm, A4.

- *2: When same paper size and speed priority mode is selected.

- *3: Comparing productivity of Versant 180 Press printing on 330 x 660 mm long paper.

Performance Package

With the Performance Package, maintain top speeds on 400 gsm media, and gain colour confidence with an inline spectrophotometer and Automated Color Quality Suite (ACQS) to confidently and efficiently produce stable and accurate colour on every job.

Maximisation of Printer Productivity with GX Print Server 2 / GX-i Print Server 2

Print server processes high capacity jobs rapidly at high resolution of 1200 x 1200 dpi, 10 bit. It handles variable printing and other high capacity jobs effortlessly and fully maximises the high productivity of the printer.

“Middle Data Format” Suppresses Capacity and Processes Jobs at High Speed

Text and images are automatically determined and managed in object units. High image quality jobs of large data capacity are processed at high speed while retaining image quality and suppressing the capacity.

High-Speed Processing Achieved through the “RIP Accelerator Board” Hardware

High-speed tuning is achieved at the hardware level, thus enabling the printer to perform at a faster speed than the physical specification of the server.

- Note: Standard equipment.

“High-Speed Serial Transfer Technology” from Print Server to Printer

Data processed at the print server is transmitted to the printer at 4.25 Gbps/channel* broadband. Errors are automatically detected and corrected, and high reliability is assured.

- *: 2 channels used in 1 colour.

Supports Long Paper of Maximum 1200 mm

The printer supports a wide variety of paper sizes, from 98 x 148 mm to 330 x 488 mm. The Multi Sheet Inserter for Banner Print* is equipped for all configurations and printing on long paper (330 x 660 mm) is also supported. The printer can handle options such as one-sided long paper printing (330 x 1200 mm) and Duplex Automatic Print of long paper (330 x 864 mm), thus expanding its capability for new applications and business.

- *: The configuration directly connected to the printer supports long paper of 330 x 1200 mm (330 x 660 mm paper for Duplex Automatic Print).

Supported sizes

Able to Handle Various Paper Weight from 52 gsm to 400 gsm

The printer handles a wide selection of media, from thin folded flyers to thick business cards. It also supports heavyweight long paper of up to 350 gsm*. It is able to meet a wide range of customer needs with its impressive paper handling ability and versatile printing possibilities.

- *: For one-sided printing of long paper of up to 330 x 660 mm from the optional Air Suction Feeder C1-DSXL or Chained Air Suction Feeder C1-DSXL-L. The supported paper weight differs depending on the feeder and paper length. For details, please check “Functions & Specifications” in the brochure.

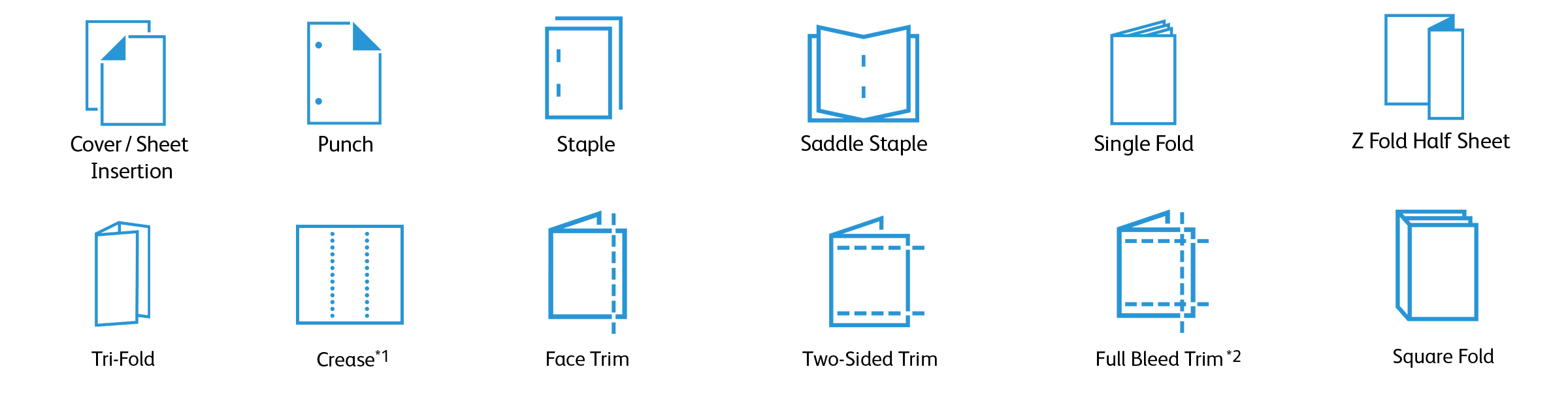

Wide Variety of Finishing Options

Versant 180i / 170i Press offers a wide variety of finishing options, including A3 Cover Sheet Insertion, Punch, Staple, Saddle Staple, Single Fold, Z Fold Half Sheet/Tri-Fold, Crease, Face Trim, Full Bleed Trim, and Square Fold. Your jobs are easily completed from print to finishing. It provides automation that keeps you productive while saving time in printing production.

- Note: Optional.

Finishing Applications

- *1: Up to 5 creases are possible for mountain fold and valley fold.

- *2: Full Bleed Trim is performed for Two-Sided Trim and Face Trim.

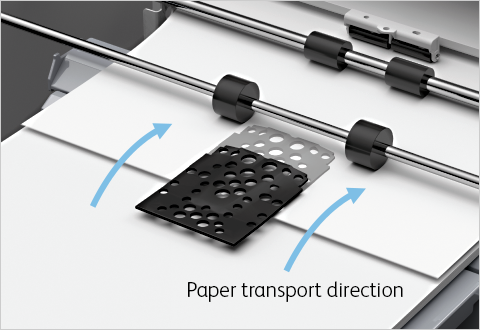

New Proprietary Technology Enables Continuous Feed Sheet by Sheet for Various Paper Types

The newly developed Air Suction Feeder uses an air suction method to handle paper. With our proprietary shuttle head shape and mechanism that draws up the paper strongly using a small amount of air, it easily separates and delivers various paper types sheet by sheet efficiently. This mechanism improves feed performance for paper types where traditional feed methods cause stress, such as paper with a lot of paper dust, pre-printed paper for offset printing using powder, paper with uneven texture, and coated paper that is prone to sticking. Stable and high-speed feed is achieved for various paper types, from lightweight to heavyweight, small-sized paper and long paper. The Air Suction Feeder*1 also supports continuous printing of long paper. It can load 100 sheets*2 of 330 x 1200 mm long paper and 800 sheets*2 of 330 x 864 mm long paper.

- *1: Air Suction Feeder C1-DSXL, Chained Air Suction Feeder C1-DSXL-L

- *2: 90 gsm paper.

High Image Quality, Automatic Processing Technology, Reliable System Maximising Uptime - Quality & Reliability

Professional 2400 dpi High Quality Resolution

The VCSEL-ROS delivers print resolution of 2400 dpi and the energy-efficient EA-Eco toner* achieves synergistic effect with toner volume control according to the coated or uncoated paper to deliver high image quality similar to offset printing.

- *: Emulsion Aggregation-Eco Toner.

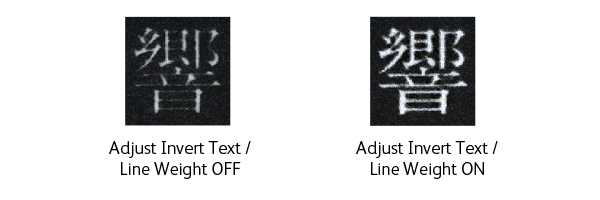

Clear Printing of Small Texts and Thin Lines

Edge enhancement:

Jaggy, which tends to occur on midtone texts and lines, is suppressed by screen processing on contours, reproducing crisp texts and lines.

Adjust Invert Text/Line Weight:

In these processes, the press mitigates crushing of white texts and fattening of black texts when the texts are small. Several levels of toner amount are available for selection for applying to the contour, so that you can set a desirable balance for better readability of texts.

1200 x 1200 dpi x 10-bit RIP Rendering

RIP resolution of 1200 x 1200 dpi and lossless compression reproduces vibrant colours without compromising the quality of the original image. 10 bit processing delivers smooth gradation.

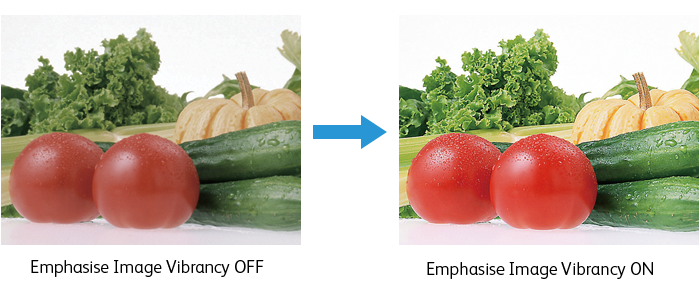

Auto Correction of Photos According to the Shooting Condition and Purpose

NIE* is used to automatically correct the contrast and colour balance of images taken with digital cameras if they appear dark, undersaturated, and colour is unbalanced. A wide variety of images can be corrected, such as colour-fogged photos taken under fluorescent lights, photos to show freshness, and photos to emphasise high definition.

- *: Natural Image Enhancement

Stable Colour Reproduction with 3D Calibration

To counteract colour fluctuations caused by temperature and humidity, Versant 180i / 170i Press provides both simple calibration using scanned colorimetric charts, as well as highly sensitive calibration using a spectrophotometer*1. It supports stable colour reproduction with the high-resolution 3D calibration*2 and feedback feature that supports both single and mixed colours.

- *1: Optional i1® Pro 3 from X-Rite, Inc.

- *2: Only with i1® Pro 3

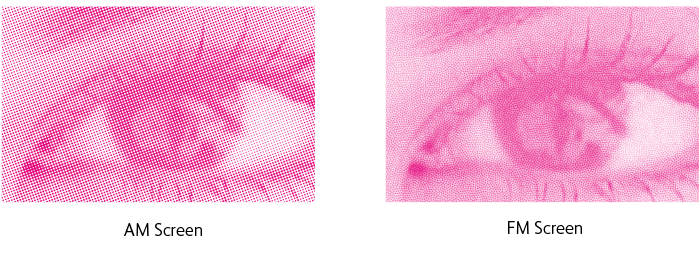

Selectable Screens According to the Object

Various screens are available for selection according to the object such as text or photo. Use our proprietary FM screen when moire patterns appear. The FM screen minimises graininess with appropriate dotdeployment according to the characteristics of xerography and renders smooth image quality.

SIQA* Saves Time with Streamlined Adjustment

By scanning special charts, SIQA will automatically calibrate the adjustment values suitable for image-to-media alignment, density uniformity adjustment and image transfer adjustment. With SIQA, operators no longer have to go through the time-consuming and iterative procedure of having to print, measure and manually adjust individual settings. This increases machine utilisation rate and improves document image quality.

- *: Simple Image Quality Adjustment.

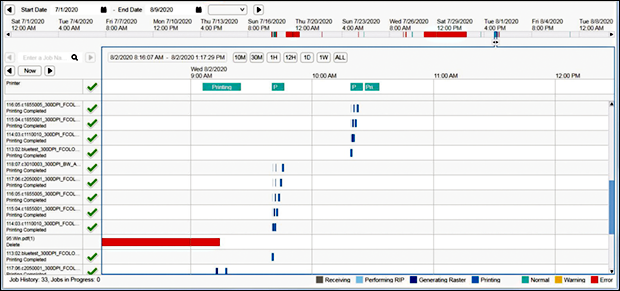

Easy Error Confirmation with Visual Log Display

The print server is equipped with a timeline function that displays job and printer status and history in chronological order. User job logs can also be easily checked on the screen, allowing for swift action when errors occur.

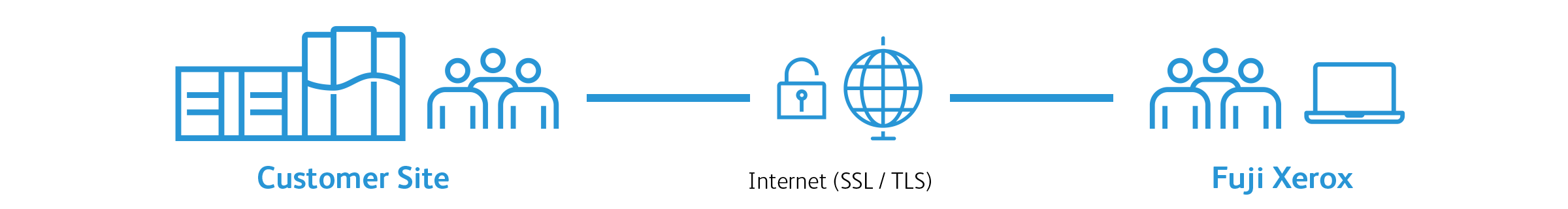

Remote Services* – Reliable Support System

FUJIFILM Business Innovation Remote Services increase machine reliability, uptime, and productivity – making it easier for us to help you make your business stronger. Our Remote Services seamlessly integrate support systems and tools with highly skilled support teams across the globe. These connections enable us to provide proactive and relevant problem resolutions through robust underlying knowledge and comprehensive product understanding.

- Transmit machine data to provide preventive maintenance, predict machine failure, and reduce the time to fix problems.

- Monitor supplies and consumable levels (such as toner) and automatically deliver them, saving time and ensuring you have what you need to keep printing, when you need it.

- Automatically report billing meters saving time and improving accuracy.

- *: Availability depends on location.

Powerful Office Functions for Smooth Performance

Supports Various Print Output

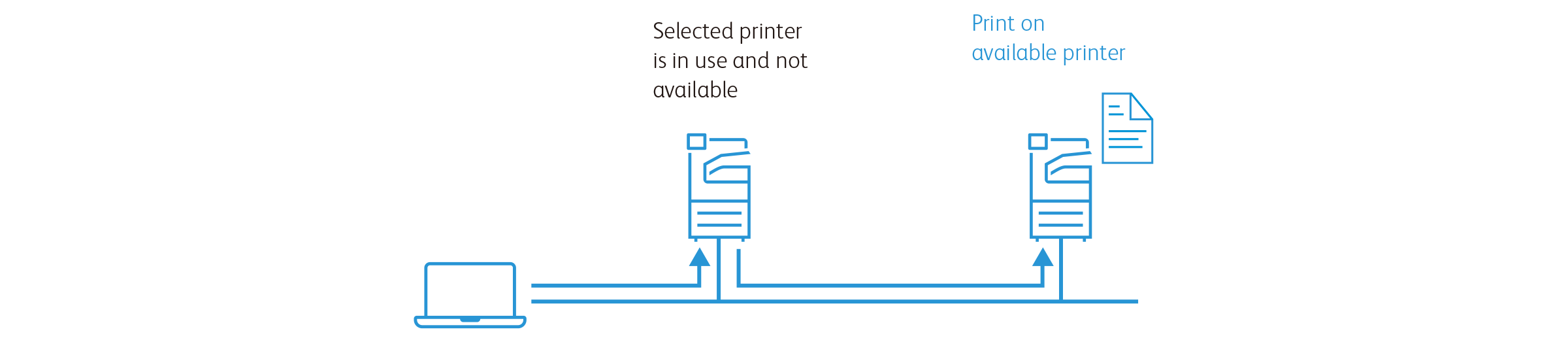

You can print office documents directly from your Windows PC without accessing the print server. After a job has been sent to the printer, you can choose private print*1 with authentication, or select the Server- less on-demand printing*1 *2 feature to print it from any machine on the network on-demand.

- *1: Operation in Authentication Mode is required.

- *2: Optional. Server-less on-demand printing is possible for print jobs only without accessing the print server. Multi-model Print Driver 2 must be used.

Server-less on-demand printing

Scan

Supports Various File Formats and Processing

Scan data can be converted to into TIFF, JPEG, DocuWorks document, PDF, and XPS*1 before sending as e-mail or saving to the computer. You can also convert scanned documents to searchable text with OCR*2, compress data to reduce transmission load, and set password in scanned documents. Scanned data can also be saved directly to USB memory*2.

- *1: XML Paper Specification

- *2: Optional.

Copy

Wide Variety of Copy Functions

- Mixed Size Copy

- Add Cover

- Booklet

- Multiple-Up

- Poster

- Copy to Tabbed Paper

You can copy on the tabs of the tab stock paper. - Repeat Image

You can copy a specific number of the original image repeatedly on one sheet of paper.

Management / Security

Links Up with Remote Authentication Server

The authentication function prevents unauthorised access and non-permitted users from using the Multifunction Device. It also calculates the total usage of each user from the Job History. As user information from the Authentication Server is available on the Versant 180i / 170i Press, it allows efficient authentication management without having to perform Authentication Settings for every Multifunction Device. The IC card reader* also allows authentication by swiping the IC card.

- *: Optional.

Various Options Available According to Needs

Feeding Options (Max. 10300 sheets)

One High Capacity Feeder Configuration

- 1. High Capacity Feeder B1-S

- – Air Assist

– Multifeed Detection

– Cabinet

– 52 to 300 gsm

– 2000 sheets x 1 tray

- 2. High Capacity Feeder C3-DS

- – Air Assist

– Multifeed Detection

– 52 to 350 gsm

– 2000 sheets x 2 trays - 3. Air Suction Feeder C1-DS

- – Air Suction

– Multifeed Detection

– 52 to 400 gsm

– 2100 sheets x 2 trays - 4. Air Suction Feeder C1-DSXL*1

- – 1200 mm Long Paper*2

– Air Suction

– Multifeed Detection

– 52 to 400 gsm

– 800 sheets + 2100 sheets - 5. HCF B1

- – A4 size

– 64 to 220 gsm

– 2000 sheets x 1 tray

Two High Capacity Feeder Configuration

- 1. 2nd High Capacity Feeder C1-DS + High Capacity Feeder C3-DS

- – Air Assist

– Multifeed Detection

– 52 to 350 gsm

– 2000 sheets x 2 trays x 2 units - 2. Chained Air Suction Feeder C1-DS-L + Chained Air Suction Feeder C1-DS-R

- – Air Suction

– Multifeed Detection

– 52 to 400 gsm

– 2100 sheets x 2 trays x 2 units - 3. Chained Air Suction Feeder C1-DSXL-L*1 + Chained Air Suction Feeder C1-DS-R

- – 1200 mm Long Paper*2

– Air Suction

– Multifeed Detection

– 52 to 400 gsm

– 800 sheets + 2100 sheets + 2100 sheets x 2 trays

- Multi Sheet Inserter for Banner Print

- – 1200 mm Long Paper*3

– 600 mm Long Paper*4

– 52 to 300 gsm

– 250 sheets

- Note: The Multi Sheet Inserter for Banner Print is equipped for all configurations.

For Multi Sheet Inserter for Banner Print only configuration and HCF B1 configuration, the options are fitted to the printer.

For all other configurations, the options are fitted at the top of the High Capacity Feeder. - *1: Long paper feeding is possible only at the upper tray.

- *2: During 1 Sided Printing. Up to 330 x 864 mm during Duplex Automatic Print.

- *3: When fitted to the printer. During 1 Sided Printing. Up to 330 x 660 mm during Duplex Automatic Print.

- *4: When fitted at the top of the High Capacity Feeder.

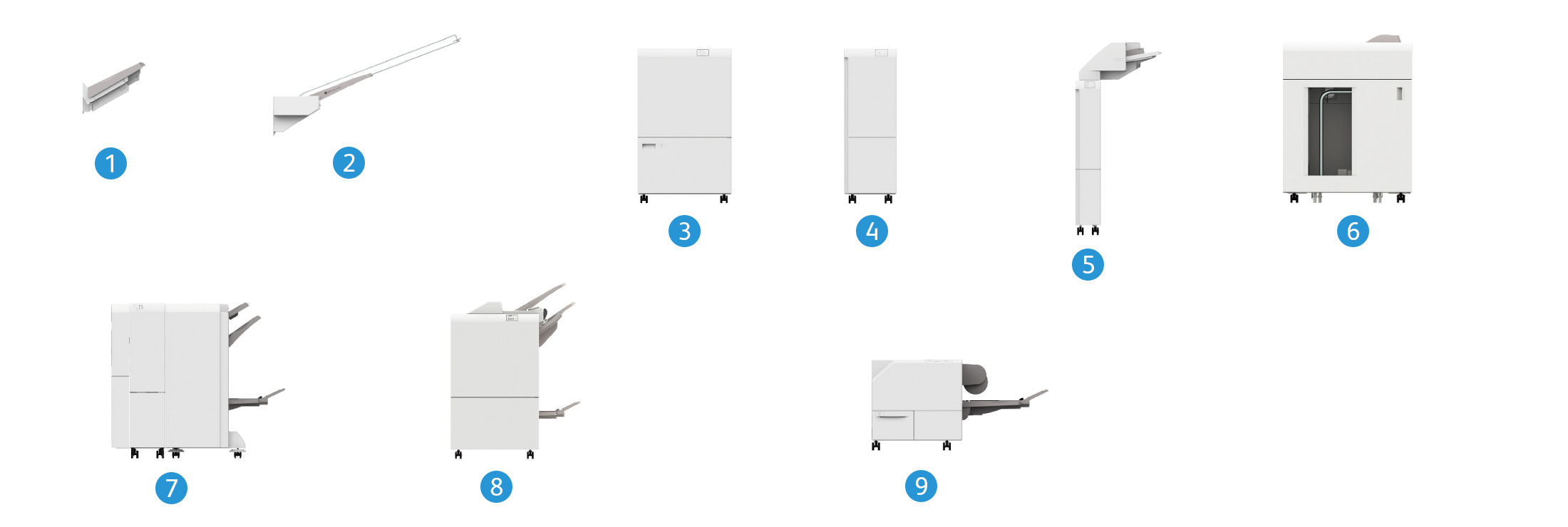

Output Options (Max. 9000 sheets)

- 1. Offset Catch Tray

- – Offset Stack

- 2. Long Catch Tray

- – Long Paper Stacking

- 3. Crease / Two-sided Trimmer D2

- – Two-Sided Trim

– Crease - 4. Interface Decurler Module D1

- – Real Time Curl Correction

- 5. Inserter D1

- – Cover / Sheet Insertion

- 6. High Capacity Stacker A1

- – 5000-sheet of Offset Stacking

– Stacker Cart

– Long Paper Stacking*1 - 7. Finisher C3 / Finisher C3 with Booklet Maker

- – Sort / Stack

– Staple

– Punch*1

– Saddle Staple / Single Fold*2

– Z Fold Half Sheet / Tri-Fold*3 - 8. Finisher D6 / Finisher D6 with Booklet Maker / Finisher D6 Plus

- – Sort / Stack

– Staple

– Punch*1

– Saddle Staple / Single Fold*4

– Z Fold Half Sheet / Tri-Fold*5

– Long Paper Stacking*1 - 9. SquareFold Trimmer D1

- – Face Trim

– Square Fold

- Note: For options and trays that can hold long paper output, please check “Functions & Specifications” in the brochure.

- Note: For 3rd Vendor Finisher, please contact your local FUJIFILM Business Innovation representative.

- *1: Optional.

- *2: For Finisher C3 with Booklet Maker.

- *3: When Folder Unit CD1 is fitted.

- *4: For Finisher D6 with Booklet Maker.

- *5: When Folder Unit CD2 is fitted.