Iridesse-Production-Press

Overview

Incredible CMYK quality and consistency.

Iridesse is the perfect choice for a full range of digital jobs. High productivity, outstanding image quality, a wide media latitude, and the reliability of the production flagship model featuring unprecedented power of expression. With robust production capabilities, Iridesse™ lets you take on complex jobs while ensuring the consistency within each print run.

The cutting edge of digital printing.

Designs featuring specialty colours with the shine of eye-catching gold, silver, and metallic. Enhance your printing projects with revolutionary metallic effects.

Iridesse Production Press – the industry’s first* 6-colour print engine – realises these printing expressions on demand, which were done mainly by offset. In addition to CMYK Dry Ink, the press offers specialty colours choices of Gold, Silver, White, Pink and Clear Dry Ink.

High productivity, outstanding image quality, a wide media latitude, and the reliability of the production flagship model featuring unprecedented power of expression make a solid difference in your business. Enhance your metallic colour gamut with the use of gold and silver to expand your CMYK capabilities. Now it’s time to make metallic colours a standard component of your design palette. In addition, the pink spot colour allows you to incorporate bright and vibrant pink hues into the design of printed materials that broadens the scope of different styles of visual expressions. Moreover, mixture of pink dry ink with CMYK colours will enable printing orange, red, violet and other colours with a vibrancy that cannot be achieved with CMYK colours alone

* Xerographic process. As of November 2017.

Features

Two Industry's First Features.

6-Colour Print Engine that Brings Unprecedented Power of Expression to Digital Printing.

In addition to CMYK Dry Ink, the press can load a maximum of two Specialty Dry Ink stations. As Specialty Dry Ink, choices of Gold, Silver, White, Pink and Clear Dry Ink are available. The press can print multiple special colours such as gold and silver in a single pass. The industry’s first 6-colour print engine provides rich colour expressions opening up the possibility of print business.

Sample of Clear Dry Ink and metallic colours realised by underlay with Gold Dry Ink

Sample of metallic colours realised by underlay with Silver Dry Ink

Dry Ink Technique that Enables Industry’s First 6-Colour Print Engine.

HD EA Dry Ink* – boasting the world’s smallest class of size – realised the difficult technique of fusing 6-layer Dry Ink on substrate while maintaining high productivity, outstanding image quality, and a wide media latitude. Small and high elasticity Dry Ink particles being controlled at the molecular level provides smooth high-definition images. By enabling low melting of various types of Dry Ink such as Gold Dry Ink and Silver Dry Ink with improved highly reflective metallic colours, the press evenly prints any colour for high definition images.

* Used for CMYK Dry Ink.

Underlay with Specialty Dry Ink realises Offset-Like Metallic Colours.

FUJIFILM Business Innovation made it possible to print Specialty Dry Ink under CMYK Dry Ink for the first time in the industry. Underlay with Gold or Silver Dry Ink mixing with CMYK Dry Ink realised highly reflective metallic colour. You can get the power of expression almost as good as specialty inks and foil stamping of offset, on demand. Unlock the beauty of metallic ink printing with revolutionary metallic silver or gold expressions.

Front: Sample of metallic colours realised by underlay with Silver Dry Ink

Back: Sample of metallic colour realised by underlay with Gold Dry Ink

Innovate CMS* realised Metallic Colours that are Almost as Good as Offset Inks.

Our innovative CMS (patent pending) reproduced the characteristics of metallic colours that represent different tones depending on the sight direction. The technique to manage the colour reproduction in multiple sight directions realised highly reflective metallic colours closer to those of offset inks.

* Colour Management System.

![]()

Iridesse Production Press was designed to raise the possibility of digital printing to a new stage through bold metallic inks. High-quality and colour-rich printing expressions including highly reflective metallic colours provide added values not only to creators but also to all of those that are in the printing business. Make designs pop with eye-catching silver and gold ink.

Iridescence (ìrədésns)

Various colour tones such as those of seashells and dragonfly wings that change with the light variance, the sight direction, and the viewing point – Rainbow colour.

Specialty Dry Inks Increase the Capabilities.

A Variety of Metallic Colours that you can Choose from the Colour Palette.

Highly reflective metallic colours that can be realised by the Specialty Dry Ink are preregistered, and you can select them easily from applications. Metallic colours found in colour catalogues such as PANTONE® METALLICS Coated and PANTONE® PREMIUM METALLICS Coated*, as well as choices of highly usable FUJIFILM Business Innovation metallic colours are available. You can customise a colour or create a new colour.

FUJIFILM Business Innovation metallic colour catalogue

* Silver Dry Ink is used for underlay.

Make Specialty Colour Applications Easily and Quickly Digital Printing.

Digital printing enables handy and speedy design of applications using specialty colours, which would take time and cost with offset.

- Multicolour printing and finishing in single pass:

This press handles printing and finishing in single pass, for a job that uses specialty colours, for which other machines would take multiple steps. You can efficiently make highly value-added applications. - Many specialty colours can be easily used:

You do not have to set each specialty colour ink on the printing machine. With this press, you can easily use various specialty colours because the press creates metallic colours by combining Gold Dry Ink or Silver Dry Ink with CMYK Dry Ink. - The colour of the Specialty Dry Ink is customer replaceable:

By allowing the user to replace the Dry Ink, the five Specialty Dry Inks* have become more easy to use.

* Gold, Silver, White, Pink and Clear Dry Ink.

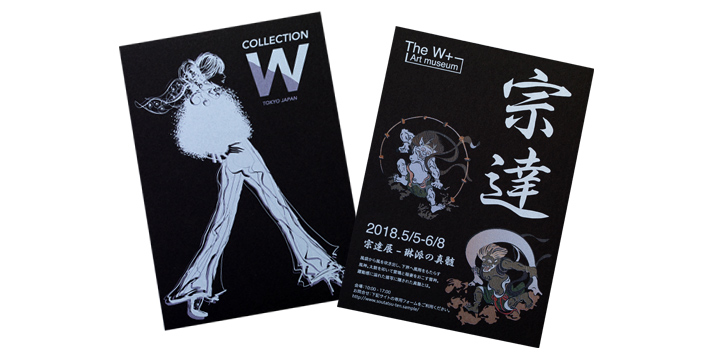

White Dry Ink and Clear Dry Ink* Bring New Possiblities of Design Expression

The press comes with White Dry Ink of a high brightness and opacity that contrasts favourably with dark stock or other special substrates. Underlay with White Dry Ink realises CMYK colours without being affected by the substrate colour. Clear Dry Ink creates a glossy-feel finish like varnish. You can expect an eye-catching design effect.

Sample of White Dry Ink underlay on black paper

* Only overlay.

Design Using Specialty Colour Exercises its Value in Variable Printing.

The use of Specialty Dry Ink for variable printing of direct mail, invitation cards, and the like provides added values such as a high appealing power required for one-to-one marketing. Using the press with our FreeFlow VI Suite*, you are able not only to print personalised documents fast but also to get printed texts that are only visible with an infrared camera or under UV/black-light with ordinary CMYK Dry Ink. Unique visual effects that provide basic level of fraud protection.

* Optional software.

Vivid Printing with Pink Dry Ink.

Pink Dry Ink can be used as specialty dry ink.

Using pink colour allows you to express in various ways, for example, cute, stylish, and elegant designs.

You can also print vivid orange, red, and violet with increased colour fidelity that could not be reproduced with conventional CMYK.

This enables the booklet cover and POP to exhibit strong appealing power with an eye catching design.

Note: “ICC profile for pink colour separation” comes bundled as standard. It can convert RGB data into CMYK plus pink data.

Design using pink

Capable of printing vivid colours that could not be reproduced with conventional CMYK

Outstanding Image Quality for your Expression.

High Printing Resolution that Realises High-Definition Images.

The high printing resolution of 2400 x 2400 dpi prints the gorgeous colours with fine dots that this press expresses without losing their beauty. More advanced VCSEL – ROS* realises both a high productivity of 120 ppm and high-definition images.

* Vertical-cavity surface-emitting lasers.

Fine Expression of Texts, Thin Lines, and Gradations with the 1200 X 1200-DPI X 10-BIT RIP Rendering.

The 1200 x 1200-dpi x 10-bit RIP rendering reproduces smooth texts, thin lines, and gradations of the source material without degrading the image quality. Combined with the excellent hardware performance of Iridesse Production Press, which is a production flagship model, this feature realises one of the best image quality among FUJIFILM Business Innovation products.

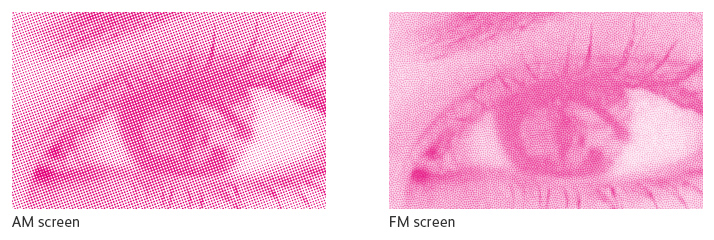

Selecting Different Screens for Individual Objects for Optimum Image Quality.

Various screens are available, from which you can select the suitable one for each object such as a text and photo. The FM screen of FUJIFILM Business Innovation is effective for moire. Granular roughness that tends to occur on FM screens is suppressed by the dot arrangement suitable for the xerography profile, realising a smooth image quality.

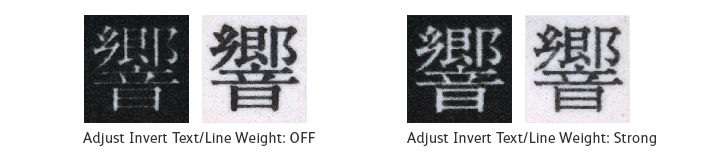

Clear Printing of Small Text and Thin Lines.

- Edge enhancement:

Jaggy, which tends to occur on midtone texts and lines, is suppressed by screen processing on contours, reproducing crisp texts and lines.

- Adjust Invert Text/Line Weight:

In these processes, the press mitigates crushing of white texts and fattening of black texts when the texts are small. Several levels of Dry Ink amount are available for selection for applying to the contour, so that you can set a desirable balance for better readability of texts.

3D Calibration Supporting Stable Colours Reproduction.

For calibration, we provide Full Width Array that automates the adjustment of colour variation as well as i1®Pro 2 – a spectrophotometer of X-Rite. High-accuracy 3D calibration and a feedback function that supports not only single colour but also mixed colours support stable colour reproduction.

Fine Colour Correction Adapted to the Design and Photos.

- Support for different CMYK colour standards:

The press supports different colour standards of the printing industry; FOGRA, SWOP 2006 and GRACoL 2006. You can make colour simulation in your desired colour space.

- Flexible colour adjustment using user adjustment curve:

You can flexibly adjust the reproduction curve of CMYK colours. Subtle adjustment of highlights is also possible.

- Adjustment of midtones of spot colours is also possible:

Industry standard spot colour libraries such as PANTONE® are available. You can also correct midtones of spot colours using the adjustment curve and target value settings.

- Automatic photo correction that is adapted to the photo scene and the use purpose:

The photo contrast and colour balance are automatically corrected. Automatic correction is also possible for colour cast that happens in indoor shooting and for the adjustment of textures such as freshness and fineness.

Speedy and Stable Provision of a Variety of Printing.

The press handles heavyweight stock printing and banner printing* and makes various finish.

* Optional.

Industry-Leading Flecibility with the Support for Lightweight and Heavyweight Stocks from 52-400 GSM.

The Iridesse Production Press supports a variety of applications including lightweight stocks for fliers and heavyweight stocks for name cards. With its media flexibility, the press can provide a variety of applications and respond to many needs.

Supporting a Variety of Paper Sizes Including Postcards and Banners.*

The Iridesse Production Press supports a variety of paper sizes ranging from 98 x 148 mm to 330 x 488 mm. The press also supports banner printing*, enabling innovative applications and business.

Sample of banner printing

* Optional. 1 side Printing: Max 330 x 1200 mm. Auto Duplex Printing: Max 330 x 729 mm.

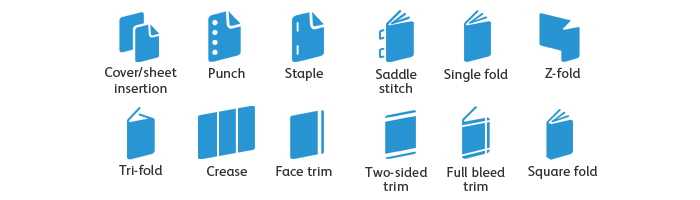

A Variety of Incline Finish.*

Finish such as crease, full bleed trim, and square fold that raise the value of applications can be done in single pass after printing, so that applications are made quickly without much trouble. Inline finish, together with the power of expression and media flexibility that Iridesse Production Press provides, raises the value of your applications.

Sample of creasing

* Optional.

Increase your Productivity

Running All Weights at Rated Speeds of 120 PPM*.

The top speed is maintained from lightweight to heavyweight stocks of 52-400 gsm. High speed is maintained even when using 6-colour Dry Ink. With the high power of expression and high productivity, the press responds to the needs of customers that demand quick delivery.

* For A4 landscape.

Maximised Uptime with Advanced Automatic Adjustments.

From the image adjustment items*1 that can be automated by Full Width Array, you can select any adjustment items at the start of a day or shift, replacing stocks, or any other scene of everyday operation. Batch processing of multiple adjustment items is possible, which reduces the maintenance work and downtime. Diagnosis results useful for preventive maintenance can be sent to the FUJIFILM Business Innovation remote maintenance service*2.

*1: Batch processing is possible for image-to-media Alignment, density uniformity adjustment, tonal reproduction curve adjustment, uniform halftone print, and image transfer adjustment.

*2: Availability depends on location.

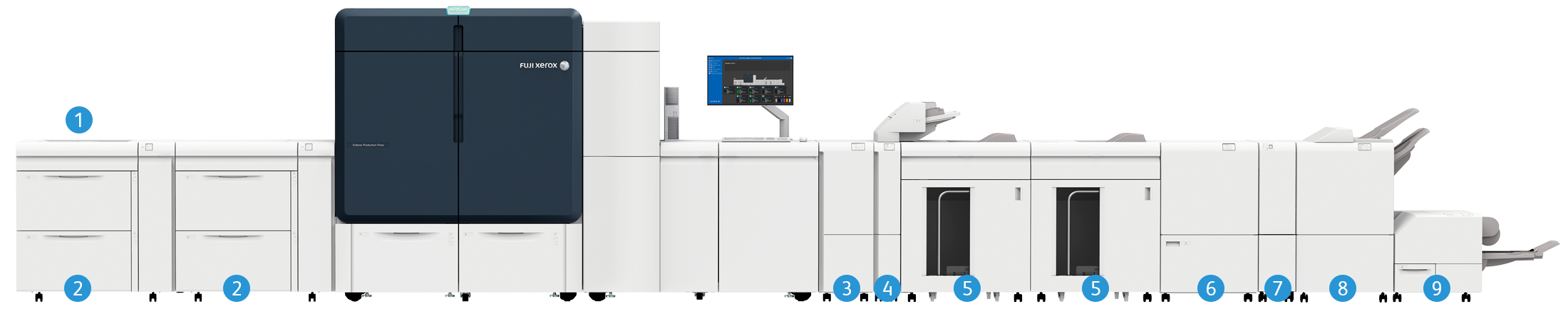

1. Attention lightAn attention light on top of your press unmistakably lets you know the status from a distance. LED colours are designed based on Colour Universal Design to make them identifiable for most people.

2. Specialty Dry InkA Specialty Dry Ink can be placed for underlay and overlay* on the left and right of the CMYK Dry Ink.

* Clear Dry Ink is only for overlay.

3. Overcoat photoreceptor drumThis features the overcoat photoreceptor drum, which is designed to enjoy a long life with an overcoat treatment on the drum surface. It provides stable and high quality of images with 1.5 times the life of our earlier models.

4. Large-diameter two-layer intermediate transfer beltThe seamlessly structured transfer belt, which provides high quality of images, enjoys two times the life of our earlier models.

- Double fly wheel:

By suppressing the vibration of the transfer belt that occurs when paper enters the transfer belt, this feature provides stable transfer on heavyweight paper, which tends to have strong vibration resulting in uneven transfer.

5. Reliable paper feeding

- Air assist:

Injected air feeds sheets one by one to reliably feed them. - Multifeed detection:

A sensor monitors paper transfer to make sure that two or more overlapping sheets are not transferred.

6. Belt-roll fusing unitThis device fuses Dry Ink reliably on the papers that runs fast. It steadily transports papers with an excellent peeling mechanism that also works for lightweight coated stock that tends to stick to the belt.

7. Monitor with improved operabilityThe monitor of the printer allows you to operate the print server as well. A monitor arm provides improved usability allowing you to operate on the monitor from different angles.

8. Steady run of papersThe paper path is designed mostly straight to achieve a lower stress on paper that runs fast. The paper path enables the steady run of heavyweight stocks as well.

- High-accuracy registration:

This feature guides the fast fed paper to the same path to achieve highly accurate front-to-back registration. - Deburring device:

While papers are running, this device deburrs trim edges of papers, which damages belts, to prevent uneven printing caused by scratches on the belt.

9. Inline cooling moduleThis module is equipped with a large heat sink. The excellent cooling effect on papers having heat-fused Dry Ink helps to prevent sticking of stacked papers as well as curling and waving that hamper steady run of papers.

10. Twin decurlerThe twin decurler determines on a real-time basis the curl of each paper, which varies depends on the media type and Dry Ink coverage. This feature helps the steady run of papers by automatically correcting the upward and downward curls with appropriate intensity.

11. Full Width ArrayVarious adjustments that had to be made manually have been automated. This feature reduces the operational labour and helps to increase the uptime and stabilise the printing quality.

[Adjustments]

- Image-to-media alignment

- Density uniformity adjustment

- Tonal reproduction curve adjustment

- Uniform halftone print

- Image transfer adjustment

- Colour calibration (single colour / multiple colours)

12. Real-time curl correction*You can make adjustment on a real-time basis while checking the amount of paper curl with your own eyes.

* You need the optional Interface Decurler Module D1.

Wide Range of Options that Expand your Business.

Print server

GX Print Server for the Iridesse Production Press

GX Print Server that makes the most of the printer productivity.GX Print Server provides high-speed job processing including 1200-dpi and 10-bit high-resolution jobs. It makes the most of the high productivity of the printer by processing a series of huge files such as variable printing.

Job edition is possible through real-time preview.

- Job Director

You can easily make imposition and pagination, as well as the creation of combined jobs by previewing logical or physical pages and dragging and dropping. - Raster Image Viewer

By previewing RIPed data and checking the images before and after adjustment, you can edit the user adjustment curve and the brightness adjustment. You can also check the printing status of the Specialty Dry Ink.

Note: The stand for GX Print Server is optional.

EX-P 6 Print Server Powered by Fiery®

Easily handle high-volume production. The powerful EX-P 6 Print Server driving the Iridesse Production Press features HyperRIP, a unique parallel-processing technology that enables blazing-fast RIP speeds.

Achieve outstanding colour accuracyGet the best out-of-the-box colour consistency and accuracy with Fiery® colour management tools.

Fiery® Color Profiler Suite allows you to calibrate your Iridesse Production Press to G7, ensuring colour accuracy throughout print runs and across multiple printers.

Features such as Fiery® ImageViewer, Fiery® Spot-OnTM and Fiery® Metallics make working with Specialty Dry Inks easy and intuitive.

Automate with seamless integrationFiery® Impose-Compose offers intuitive, visual document preparation and simplifies labour-intensive document assembly.

The Fiery® server integrates with technologies such as the FreeFlow Digital Workflow Collection.

Use Fiery® JDF technology or the Fiery® API to automate and integrate your business and print processes to drive better business results.

Feeding/Finishing options

Feeding options

1. Bypass Tray*

* Option of High Capacity Feeder C3-DS.

2. High Capacity Feeder C3-DS / 2nd High Capacity Feeder C1-DS

- Air assist

- Multifeed detection

Note: Stocks of 400 gsm or less is fed from the standard paper trays.

Finishing options

3. Interface Decurler Module D1

- Real-time curl correction

4. Inserter D1

- Cover/Sheet Insertion

5. High Capacity Stacker

- 5000-sheet of offset stacking

- Available in single and dual combinations

- Stacker cart

6. Crease/Two-sided Trimmer D2

- Two-sided trim

- Crease

7. Folder Unit CD2

- Z-fold/tri-fold

8. Finisher D6 / Finisher D6 with Booklet Maker

- Sort/stack

- Staple

- Punch*1

- Saddle stitch/single fold*2

*1: Optional.

*2: For Finisher D6 with Booklet Maker.

9. SquareFold Trimmer D1

- Face trim

- Square fold

Offset Catch Tray

- Offset output

Long Catch Tray

- Long paper output

Note: Offset Catch Tray is provided for cases that do not require finishing.

Note: For 3rd Vendor Finisher please contact your local FUJIFILM Business Innovation representative.

Finishing applications

Note: Full bleed trim is made by two-sided trim and face trim.

Not just the machine – What FUJIFILM Business Innovation provides

FUJIFILM Business Innovation contributes to better efficiency of your printing business in various stages of printing workflow.

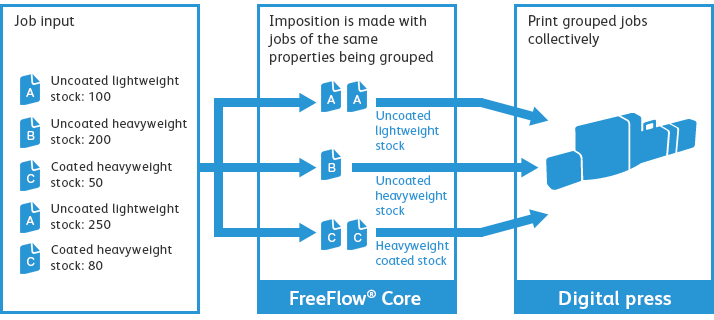

Case1: Bundling jobs of the same properties to streamline the printing operation.

The FUJIFILM Business Innovation system bundles jobs of the same properties such the media type, size, and paper weight as well as the type of finish, minimising the labour of setting stocks and changing the finisher. The system maximises the productivity of digital printing that supports varied short-run jobs, shortening the delivery period.

Note: FreeFlow Core: Optional software automates and manages the printing workflow that involves job input, prepress, printing, and finishing.

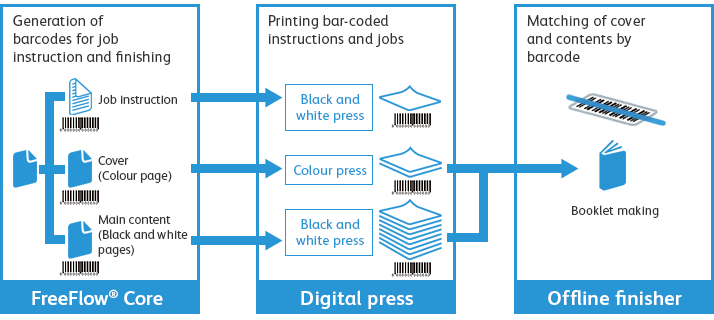

Case2: Provision of better efficiency in booklet making using an offline finisher.

Finisher barcodes facilitate booklet making when using an offline finisher for the production of documents. The finisher barcodes prevent errors such as misplaced and missing pages regardless of user skills, providing better quality of applications.